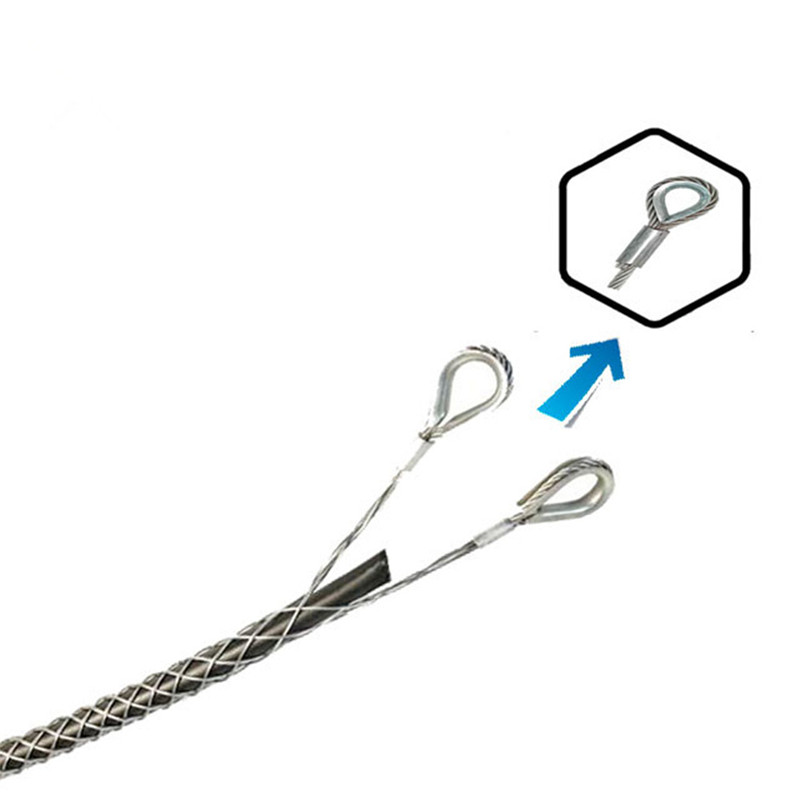

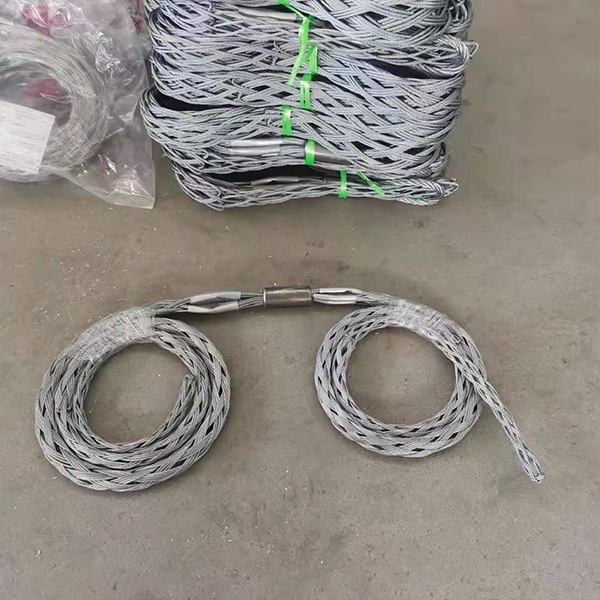

Double eye hose restraint High Voltage Cable Socks

Short Description:

Whip Stops are a great way to restrain high pressure hoses. Whip Stops have a unique design that prevents the very real and unpredictable whipping of a high pressure hose during a failure.

| P/N | HOSE OD { INCHES } | HOSE OD MM | Max OD | GRIP LENGTH | EYE LENGTH | TOTAL LENGTH | NUMBER OF PLIES | APPROX WEIGHT | AVERAGE BREAKING STRENGTH |

| 3/8" | 5/16" - 1/2" | 8-14 MM | .70" | 12.5 | 4 | 16.5 | 8X3 | 1/4 LB | 4200LBS |

| 1/2" | 1/2" - 3/4" | 14-20 MM | .85" | 18 | 4.5 | 22.5 | 8X3 | 1/4 LB | 4200LBS |

| 7/8" | 3/4" - 1.1/8" | 20-30 MM | 1.4" | 20 | 6 | 26 | 12X2 | 3/4 LB | 6200LBS |

| 1" | 1.1/8" - 1.1/2" | 30-40 MM | 2" | 27 | 8 | 35 | 12X2 | 1 LB | 12000Lbs |

| 1.1/4" | 1.1/2" - 1.7/8" | 40-50 MM | 2.5" | 32 | 8 | 40 | 12X2 | 1.1/4 LB | 12000Lbs |

| 1.1/2" | 1.7/8" - 2.3/8" | 50-60 MM | 3" | 41 | 11 | 52 | 12X2 | 2.1/4 LBS | 17000 Lbs |

| 2" | 2.3/8" - 2.3/4" | 60-70 MM | 3" | 43 | 11 | 54 | 12X2 | 2.1/2 LBS | 17000 Lbs |

| 2.1/2" | 2.3/4" - 3.3/8" | 70-85 MM | 3.75" | 43 | 13 | 56 | 12X2 | 5.1/4 LBS | 17000 Lbs |

| 3" | 3.3/8" - 3.7/8" | 85-100 MM | 4" | 58 | 17 | 75 | 12X2 | 5.1/4 LBS | 26000LBS |

| 4" | 4.3/4" - 5.1/2" | 120-140 MM | 6.25" | 71 | 19 | 90 | 16X2 | 7.1/2 LBS | 30000LBS |

| 6" | 5.1/2" - 7" | 140-180 MM | 8" | 79 | 19 | 98 | 16X2 | 8 LBS | 30000LBS |

Please follow these precautions prior to using any high-pressure hose:

1. Confirm all hoses, fittings, and safety devices are rated for the specific requirements and inspect all items to ensure they are in proper working order.

2. Make sure all couplings are matched properly. (Do not use mismatched couplings.) Double-check torque on clampMakes. Make sure fittings and clamps are not worn out. Never assume that the fittings were installed properly; check for yourself.

3. Use quality safety devices to prevent whipping if a connection fails.

4. Hose should be kept free of oil and grease to help prevent deterioration. Keep hose clear of items that can cause abrasion.

5. Confirm all couplings are properly secured and safety devices are in place prior to adding pressure.

6. Above all, NEVER, NEVER, NEVER disconnect a coupling under pressure. Confirm without a doubt that pressure has been removed prior to uncoupling. Keep the safety device in place!

7. Make sure all personnel are aware of hazards and are properly trained on equipment usage.

Prevent accident, injury, and death! These are the best high-pressure hose restraints available, because the stocking style woven steel grips the hose securely over the larger area. Abrasion and wear and tear usually take place near fittings, which may result in a rupture. If this happen within the covered area, additional safety occurs that would never occur with a standard whip check. The woven steel can also help prevent abrasion to the hose underneath.

These Whip Socks are not restricted to just air hoses, but can be use on any application where high-pressure hoses are use, air, water, hydraulic, slurry, etc. The key is the two mounting points and the long gripping area. Obviously the two anchoring point and shackles must be rated for the application.

(Whip Socks can also be use as a gripping/pulling aid when pipes are to be pulled into position in very awkward places)

Standard whip checks allow a great amount of whip occur, but the dual leg Whip Sock keeps the hose under complete control. This could mean the difference between life and death.

Your safety is our priority. For this reason, LH hose restraints only use a stocking type hose restraint. This style of hose restraint is far superior to cable or sling-type whip checks which do not adequately restrict hoses from whipping. In addition to restraining the hose the four-eye restraint, which covers the entire hose, also offers abrasion prevention to the hose underneath. Our stocking type hose restraints are designed for heavy-duty operations in a range of industries and are suitable wherever high-pressure hoses are utilised. Examples of applications include restraining high-pressure hoses dispensing water, air, sand, steam, concrete etc, and for use with hydraulic systems. LH hose restraints are available in both two-eye and four-eye configurations. The two-eye style, available in a range of standard sizes, meets the essential safety elements of two mounting points and a long gripping area. Four-eye hose restraints offer a higher level of safety as the entire length of the high-pressure hose is covered. They are custom made for your specific requirements and to your individual specifications. Details you need to provide are 'hose outside diameter' and 'length from shackle point to shackle point'.