Professional China China Factory Produced Whipcheck Safety Cable 2mm-8mm Galvanized / Stainless Steel Wire Rope Assembly Hose

Short Description:

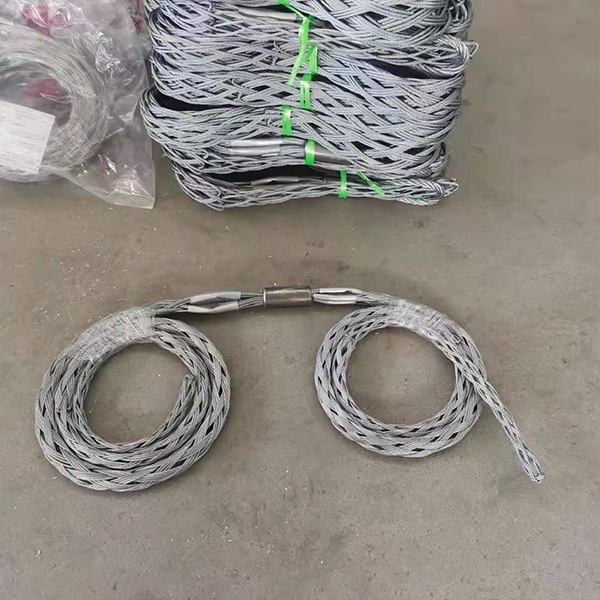

Whipcheck – safety slings are a positive safe – guard for hose connections. These strong steel cables prevent hose whip in case of accidental separation of coupling or clamp device.

Our firm sticks on the theory of “Quality will be the life in the enterprise, and status could be the soul of it” for Professional China China Factory Produced Whipcheck Safety Cable 2mm-8mm Galvanized / Stainless Steel Wire Rope Assembly Hose, Good quality, timely services and Aggressive price tag, all win us a excellent fame in xxx field despite the international intense competition.

Our firm sticks on the theory of “Quality will be the life in the enterprise, and status could be the soul of it” for China Wire Rope Assemblies, Stainless Steel Wire, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our solutions or would like to discuss a custom order, make sure you feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.

Whipcheck safety cables have been used for many years on air compressor hoses to prevent hose ends from ‘whipping’ if the coupling blows out of the hose.

Fitting the Whipcheck safety cables correctly is critical to their performance. The loop ends should be placed as far down the hose as possible. With the Hose to Hose type, the ferrule in the centre of the Whipcheck should lay at the same point as the joint between the two hoses.

The standard materials of construction are galvanised steel wire, plated steel springs and aluminium ferrules. However, Whipcheck are available in a variety of different styles including Stainless Steel and copper ferrules for marine and applications where the risk of the steel cables sparking is not acceptable.

Whipcheck Safety Cables are available in two cable diameters and a number of different configurations. Whipcheck offer additional safety for compressor hoses in enclosed or critical enviroments.

Whipcheck safety cables offer additional safety for compressor hoses in enclosed or critical environment.

Whipcheck safety cables have been used for many years on air compressor hoses to prevent hose ends from ‘whipping’ if the coupling blows out of the hose.

Whipcheck safety cables are available in 1/8″ (3.2mm) and 1/4″ (6.35mm) cable diameters and in two basic configurations – hose to hose and hose to tool. Hose to Hose are used at the joint between two hose assemblies. Hose to Tool are used at the junction between the hose and the tool but are also very important at the compressor end. The compressed gas can be very hot causing the hose to soften which in turn can lead to an increased possibility of failure.

Fitting the Whipcheck safety cables correctly is critical to their performance. The loop ends should be placed as far down the hose as possible. With the Hose to Hose type, the ferrule in the centre of the Whipcheck should lay at the same point as the joint between the two hoses.

The standard materials of construction are galvanised steel wire, plated steel springs and aluminium ferrules. However, Whipcheck are available in a variety of different styles including Stainless Steel and copper ferrules for marine and applications where the risk of the steel cables sparking is not acceptable.

We also supply large whip check for 4″, 6″ and 8″nb hose.

We can also offer non-standard versions, made to customer specification, if large quantities are required.

Hose Safety Whip Checks are the trusted industry standard in air hose safety. With 4 adjustable sizes and two different end styles, ware sure to have a cable that fits into your air hose configuration. Spring loop ends adjust to fit snug around a variety of hose diameters.

Size Specifications:

| product name | size | Material | Wire rope diameter(mm) | Overall length(mm) | Spring lengthMM) | Spring outer diameter(mm) | Spring thickness(mm) | Suitable pipe diameter size | Destructive power(KG) | ||

| whipcheck | 1/8″ * 20 1/4″ | Galvanized carbon steel | 3 | 510 | 180 | 12 | 1.2 | 1/2”-1 1/4” | 700 | ||

| whipcheck | 3/16″ *28″ | Galvanized carbon steel | 5 | 710 | 240 | 18 | 2.0 | 1/2”-2” | 1400 | ||

| whipcheck | 1/4″ *38″ | Galvanized carbon steel | 6 | 970 | 350 | 18 | 2.0 | 1 1/2”-3” | 2200 | ||

| whipcheck | 3/8″*44″ | Galvanized carbon steel | 10 | 1110 | 310 | 25 | 2.0 | 4” | 3300 | ||

Product construction and testing

LH Safety – Cable Hose Restraints also known as Whip Checks are stocked as well. We recommend whipchecks be used only on AIR HOSES carrying no more than 200 PSI. Any other use is at your own risk.

Usage

Whip check safety cable is designed specially to prevent hose connections from whipping if the hoses or couplings failed to hold. The failure usually occurs with high pressure and will make hoses or equipment shake violently which may cause serious injury for people or the nearby coupling & equipment.

Package

Our firm sticks on the theory of “Quality will be the life in the enterprise, and status could be the soul of it” for Professional China China Factory Produced Whipcheck Safety Cable 2mm-8mm Galvanized / Stainless Steel Wire Rope Assembly Hose, Good quality, timely services and Aggressive price tag, all win us a excellent fame in xxx field despite the international intense competition.

Professional China China Wire Rope Assemblies, Stainless Steel Wire, We are going to initiate the second phase of our development strategy. Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. If you are interested in any of our solutions or would like to discuss a custom order, make sure you feel free to contact us. We have been looking forward to forming successful business relationships with new clients around the world in the near future.